Understanding Systematic and Random errors

Errors are an inevitable part of any experimental process, and understanding and managing them is crucial for obtaining reliable results. Broadly, errors can be categorized into systematic and random errors. This article serves as an introduction to the concept of errors in experimental design, setting the stage for a deeper exploration of replication, randomization, and blocking.

Types of Errors

Random Errors Random errors arise from unpredictable and uncontrollable variations in the experimental process. These errors can occur due to fluctuations in measurement instruments, environmental changes, or inherent variability in the subjects being studied. For example, slight variations in temperature or humidity during an experiment could cause random errors in the results.

Systematic Errors Systematic errors, on the other hand, are consistent and repeatable errors that occur due to flaws in the experimental setup or procedure. These errors can significantly bias the results and are often harder to detect and correct. Common sources of systematic errors include:

- Instrument Calibration Issues: If an instrument is not calibrated correctly, all measurements taken with it will be consistently off.

- Biased Sampling: When the sample drawn does not represent the population. For example, if a chemical mixture is not stirred properly before taking a sample, the sample might not reflect the true composition of the mixture.

- Procedural Flaws: Consistently incorrect application of a procedure across all experimental units.

Impact of Errors on Experimental Results

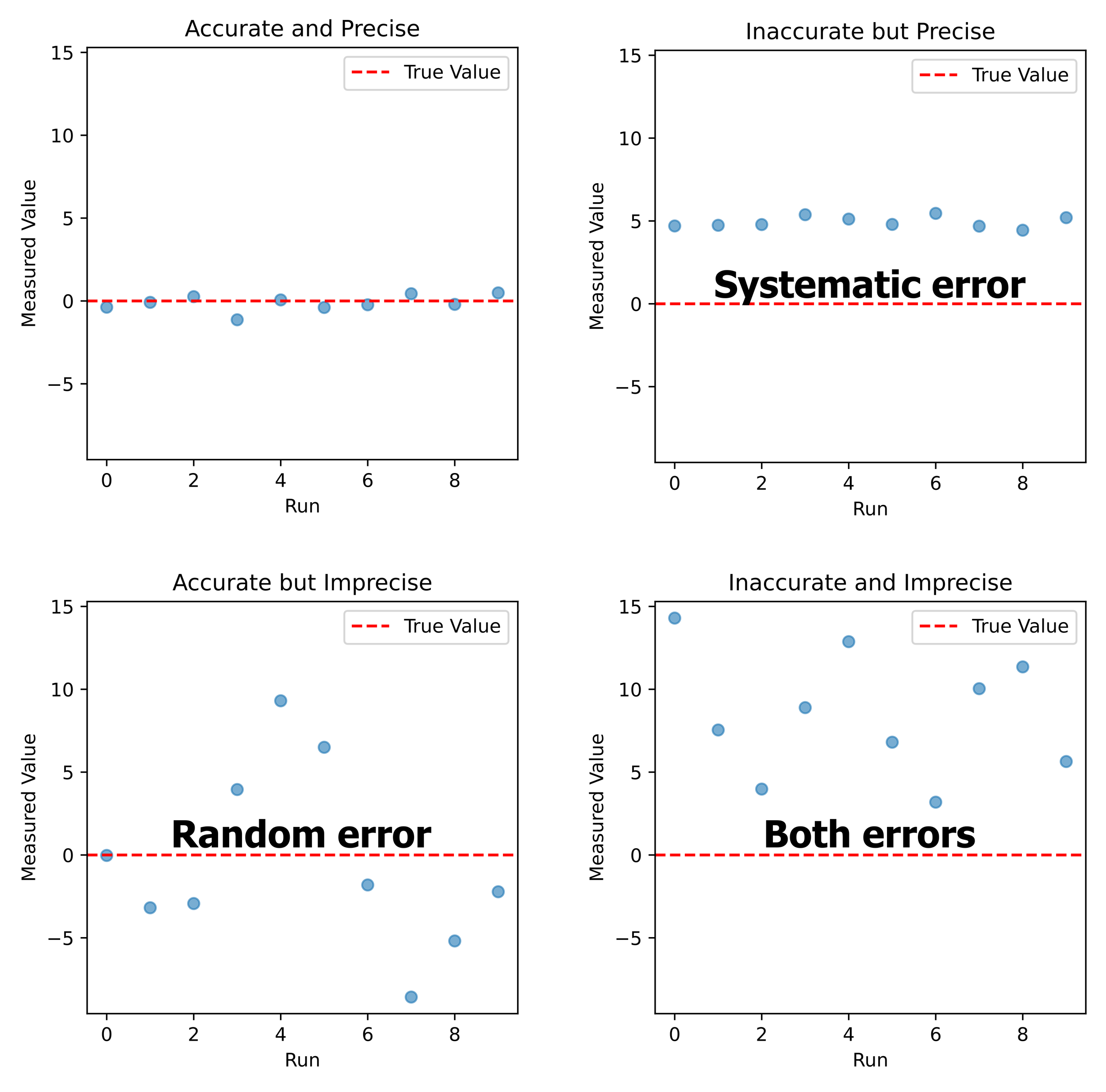

Accuracy vs. Precision Accuracy refers to how close the experimental results are to the true value, while precision denotes how reproducible the results are. Random errors typically affect precision, making the results more variable, whereas systematic errors affect accuracy, causing a consistent deviation from the true value.

Bias and Variability Errors contribute to both bias and variability in experimental outcomes. Bias results from systematic errors, leading to consistently skewed results. Variability, influenced by random errors, results in a spread of values around the true measurement.

Error Management

First, you need to identify all potential sources of errors. Make a list of all the variables that could affect your experiment. Let us say you would like to determine factors that affect the pot life of a coating system. The pot life of a coating system refers to the amount of time you have to use the mixed coating material before it starts to harden and becomes unusable. Variables that could affect the reproducibility of the measurements include:

Random Errors

- Environmental Fluctuations: Slight changes in temperature or humidity during the pot life measurement.

- Instrumental Variations: Minor, unavoidable fluctuations in the performance of the measuring instruments.

- Human Error: Accidental deviations in following procedures, such as slightly different stirring times or weighing errors.

Systematic Errors

- Instrument Calibration Issues: If the device used for measuring pot life is not accurately calibrated, all measurements will be consistently incorrect.

- Consistent Environmental Conditions: If the temperature or humidity in the testing environment is not controlled, it could systematically affect the pot life. For example, if you take measurements on two consecutive days, and one day is rainy while the other is hot, the pot life measurements taken on the hot day will be shorter due to the increased reaction rates that come with higher temperatures.

- Inconsistent Procedures: Using inconsistent mixing procedures or tools that introduce a systematic bias, such as always mixing for too short or too long.

- Material Consistency: Variations in the batch quality of the coating materials.

There is no way to eliminate all these sources of errors but there are ways to deal with them, minimizing there impact and still recording high quality results.

Strategies for Error Management

In addition to a maintenance and calibration schedule and developing test procedures that are as accurate as possible, there is another key principle when it comes to error management: “Block what you can and randomize what you can’t.”

This principle emphasizes the importance of controlling for known sources of variability (blocking) and using randomization to mitigate the impact of unknown or uncontrollable factors.

In fact, there are 3 key principles in DoE. Blocking, randomization and replication. We take a look at those in more detail in the next blog post.