Central Composite Design vs. Box-Behnken Design

Response surface designs help you capture curvature in your experiments—something that traditional factorial designs can’t do on their own. We’ve already explored how central composite designs extend factorial designs with star points and center runs to model quadratic relationships. But Central Composite Design (CCD) isn’t the only option when you need to map curved response surfaces.

Box-Behnken Design (BBD) offers an alternative approach with its own advantages. Both are widely used in Response Surface Methodology, but they differ fundamentally in structure and practical implications. Understanding these differences will help you choose the right tool for your specific optimization challenge.

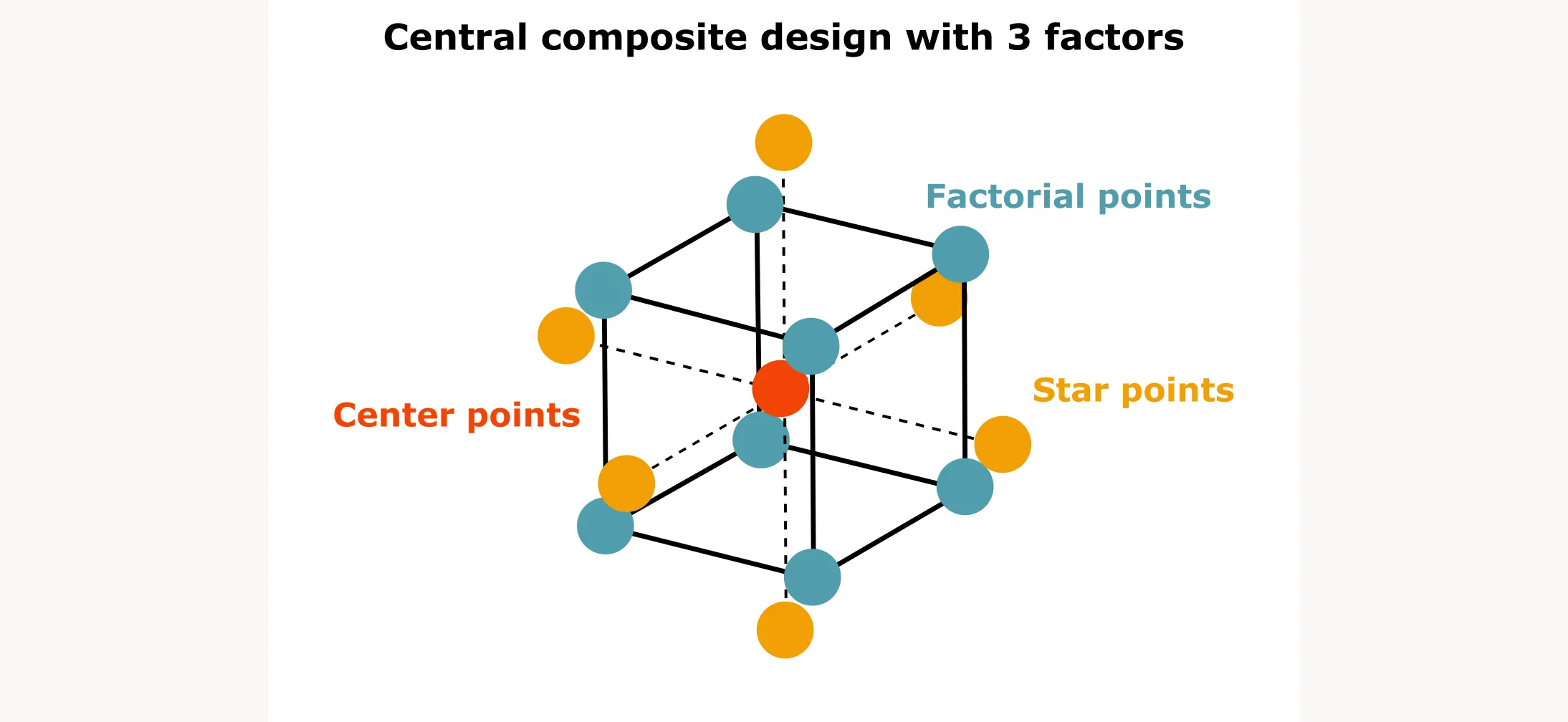

What is Central Composite Design?

Let’s start with a quick recap. A Central Composite Design builds on a factorial foundation—you can think of it as a factorial design (full or fractional) at its core, extended with two additional types of points:

- Factorial points: The corners of your design space (coded as ±1)

- Center points: Multiple runs at the center of the design space (coded as 0)

- Star (axial) points: Extended points that reach beyond the factorial corners (coded as ±α)

This structure allows you to fit a quadratic model and identify optimal settings. The star points extend outside the original factorial range, which means you’re exploring conditions beyond what you initially defined as “high” and “low.” As we covered in the CCD step-by-step example, you can adjust the distance of these star points (α) to create a rotatable design (uniform prediction precision in all directions) or a face-centered design (α = 1, keeping everything within bounds).

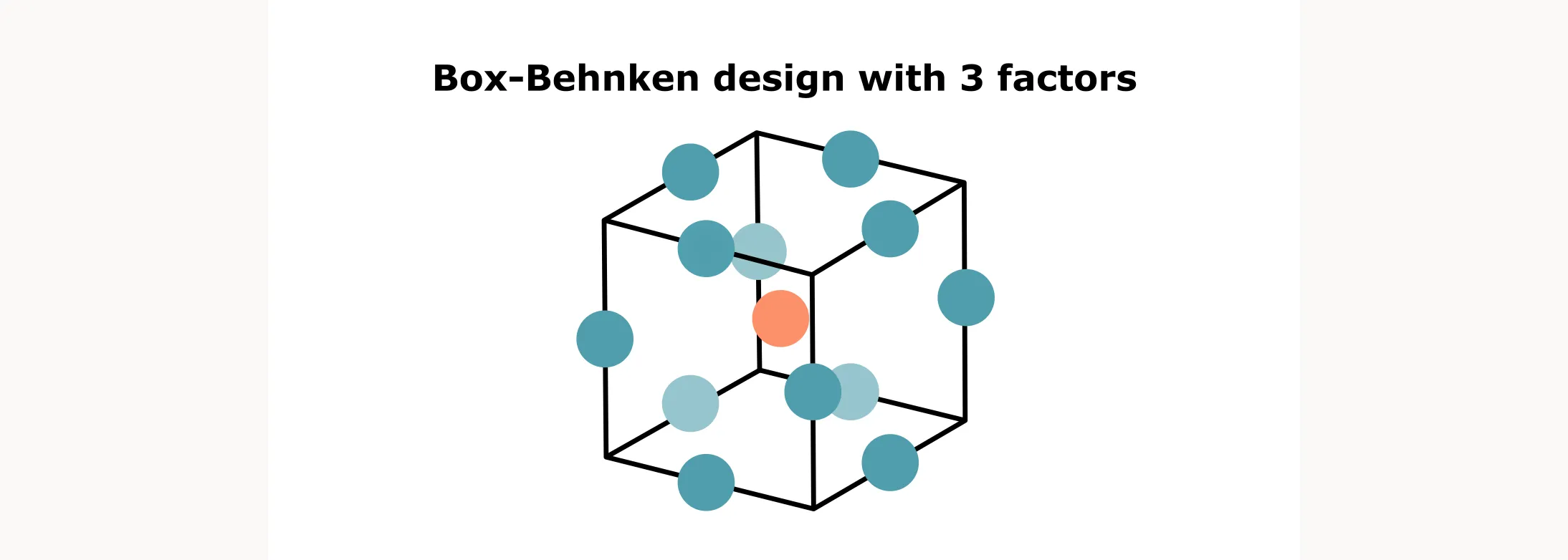

What is Box-Behnken Design?

Box-Behnken Designs take a fundamentally different approach. Instead of starting with a factorial base and extending outward, BBD places experimental runs at the midpoints of the edges of your design space.

Think of a cube: BBD doesn’t test the corners or extend beyond the cube like CCD does. Instead, it tests points along the middle of each edge. For a three-factor design, you’d test at the midpoint of each of the 12 edges of the cube, plus center points for estimating error.

This means BBD has two important characteristics:

- No extreme corner points: You never test conditions where all factors are simultaneously at their maximum or minimum values.

- No extensions beyond the design space: All experimental runs stay within the boundaries you originally defined.

These features make BBD attractive when you’re working near the limits of safe operating conditions or when pushing all factors to extremes simultaneously might be risky or expensive.

Key Differences Between CCD and BBD

Let’s break down the practical differences that matter when you’re choosing between these designs.

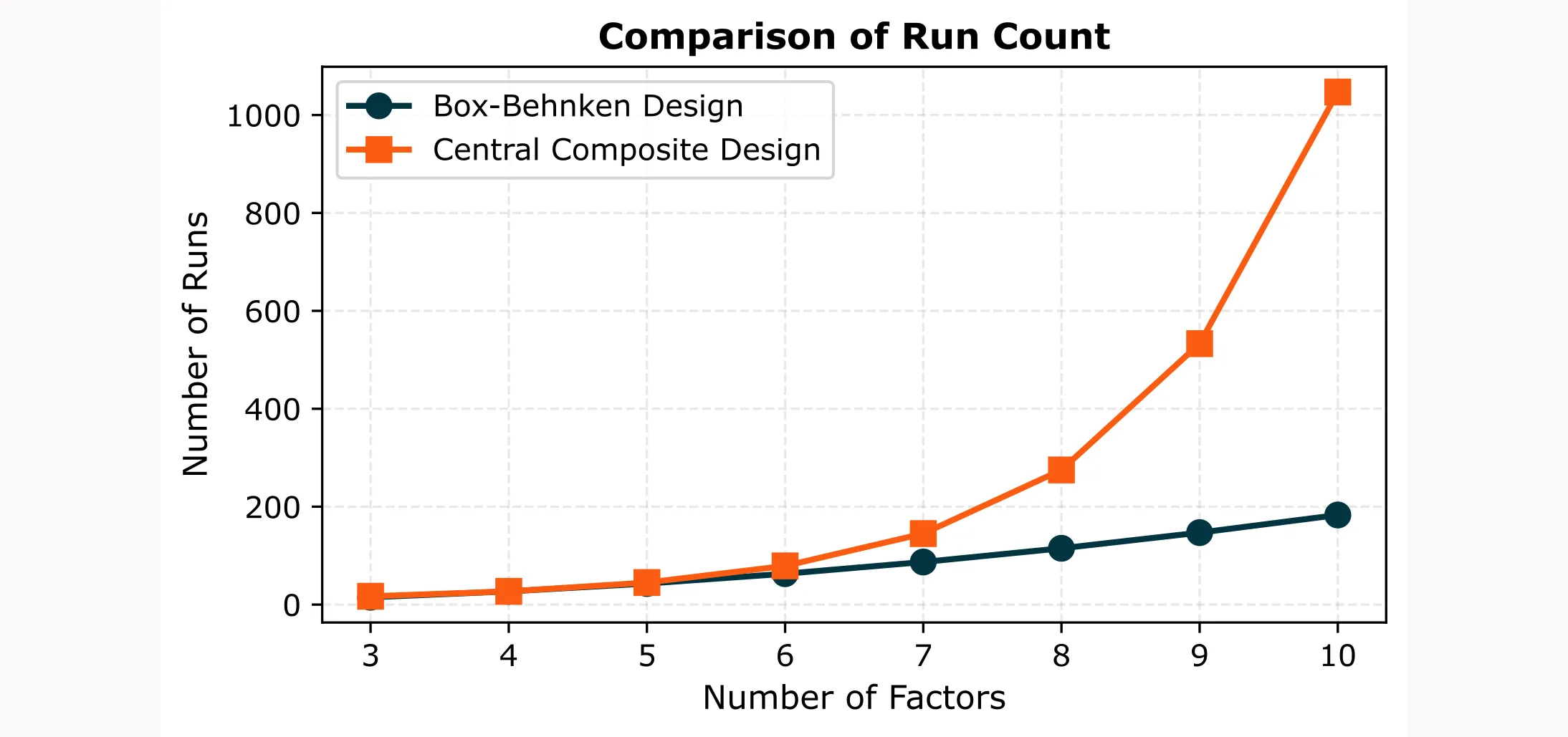

Run efficiency

Run count is comparable between the two designs for smaller experiments, but the difference grows substantially as you add factors. For response surface methodology, it’s generally recommended to work with no more than 6 factors. If you’re dealing with more potential factors than that, use screening experiments (like the fractional factorial designs we discussed earlier) to identify the most important ones before moving to response surface designs.

| Factors | Box-Behnken | CCD |

|---|---|---|

| 3 | 15 | 17 |

| 4 | 27 | 27 |

| 5 | 43 | 45 |

| 6 | 63 | 79 |

| 7 | 87 | 145 |

| 8 | 115 | 275 |

| 9 | 147 | 533 |

| 10 | 183 | 1047 |

The difference is modest. For four factors, both designs require about 27 runs. Up to six factors, the run counts remain similar. Beyond that point, CCD requires significantly more runs as shown in the comparison below.

Sequential experimentation

This is where CCD shines. Because CCD is built on a factorial foundation, you can take an iterative approach:

- Start with a fractional factorial design to screen factors (as we covered in the fractional factorial example)

- Analyze the results and identify important factors

- Add more factorial runs if needed to de-alias confounded effects

- Once you’re confident in your factorial understanding, add the star points to capture curvature

- Add center points at any stage to assess pure error

This sequential approach is powerful when you’re working in unfamiliar territory. You’re not locking yourself into a fixed design structure upfront. Instead, you learn progressively and adapt your experimental plan based on what you discover.

With Box-Behnken Design, you don’t have this flexibility. BBD doesn’t decompose into simpler building blocks—it’s an all-or-nothing structure. You commit to the full design from the start, which means you need to be more confident about which factors matter before you begin.

Operating within safe boundaries

Box-Behnken Design’s structure offers a distinct safety advantage: you never test extreme combinations where all factors are pushed to their limits simultaneously.

Let’s say you’re optimizing a chemical reaction. Testing high temperature, high pressure, and high catalyst concentration all at once might create unsafe conditions or push equipment beyond its rated capacity. BBD avoids these extreme corners entirely while still allowing you to model curvature.

CCD, on the other hand, includes factorial points at all corners and extends even further with star points. If your system has genuinely dangerous or infeasible extreme conditions, this can be a problem. You can mitigate this with a face-centered CCD (α = 1), which keeps star points within bounds, but you’ll still test all corner combinations.

This makes BBD particularly attractive for:

- Chemical processes with safety constraints

- Equipment operating near its rated limits

- Expensive materials where extreme combinations waste resources

- Biological systems where extreme conditions cause irreversible damage

Which Design Should You Choose?

In most practical situations, Central Composite Design is the more versatile choice, especially when you’re not entirely sure what your system will do. The key advantage is sequential experimentation—the ability to start small and expand your design based on what you learn.

Choose CCD when:

- You’re in the early stages of understanding your system

- You want the flexibility to build your design incrementally

- Sequential experimentation makes sense for your project timeline and budget

- Testing extreme conditions is safe and feasible

- You can tolerate or even want to explore beyond your initial boundaries

Choose BBD when:

- You’ve already done screening and know which factors matter

- Extreme combinations of all factors are genuinely problematic

- You need to stay strictly within defined boundaries

- Run count efficiency matters more than sequential flexibility

- You’re optimizing a well-characterized process where the risks of extreme conditions are known

The Practical Reality

The biggest advantage of Central Composite Design isn’t just the run count or the mathematical properties—it’s the flexibility to start small and expand as you learn. When you’re exploring a new system, you rarely know upfront whether you’ll need to model curvature at all. Maybe a simple factorial model will be enough. Maybe you’ll need full quadratic terms. With CCD, you don’t have to guess.

You can start with a fractional factorial to screen. If that’s sufficient, stop there. If you need more resolution, add factorial runs. If you still can’t find the optimum or you detect significant curvature, add the star points to complete the CCD structure.

Box-Behnken Design requires more upfront commitment. You need to be confident about which factors to include and that a quadratic model will be necessary. If you’re working in that kind of mature, well-understood system—and extreme conditions are a concern—BBD is an excellent, efficient choice.

But when in doubt, CCD’s sequential nature makes it the safer bet. You can adapt as you go, which is often more valuable than saving a handful of experimental runs.